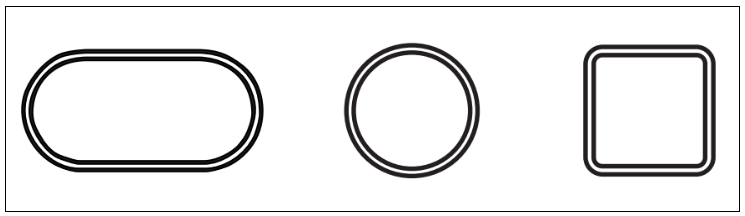

Oval Hollow Section Metal Tubes

Chair

- Light weight high strength structures

- Complex bends to suit various ergonomics

- Single piece joint free structure

- Waiting chair

- Visitor chair

- School chair and desk

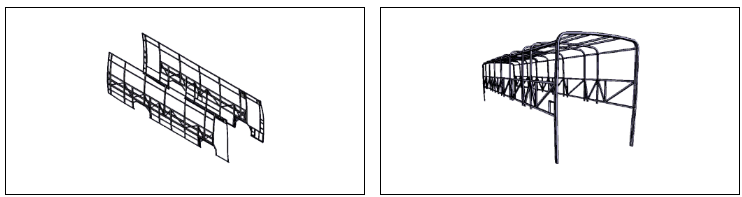

Structure Bend parts

- High tensile material

- Single piece joint free

- Multiple radius tangential bends

- Upto 14m long component

- A-Pillar

- U-truss

- Front and rear structure parts

Construction Equipments

- Multiple radius tangential bends

- High-quality A-Class aesthetic finish

- FOPS & ROPS standards complaince

- Heavy-Duty Durability

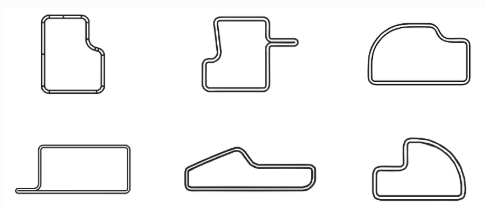

Gas Stove Tubes

- Leak proof ERW tube

- Leak proof connectors

- Galvanised ready to use component

Oval Hollow Section (OHS) Metal Tubes are a type of structural tube with an oval-shaped cross-section, offering a unique blend of strength, aesthetic appeal, and versatility. While they share many applications with Square Hollow Sections (SHS) and Circular Hollow Sections (CHS), OHS tubes are often preferred for specific purposes due to their distinctive shape.

Below are the key applications of Oval Hollow Section (OHS) Metal Tubes:

1. Architectural and Aesthetic Applications

OHS tubes are widely used in architectural and design-oriented applications because of their modern and sleek appearance. Their oval shape provides a distinct aesthetic that is highly sought after in contemporary buildings and structures.

Key Architectural Uses:

- Building Facades & Curtain Walls: OHS tubes are often used in the construction of facades, exterior frameworks, and curtain walls of buildings to create a modern look with strength.

- Interior Design: The aesthetic appeal of OHS tubes makes them popular in interior design for creating decorative columns, frames, banisters, and partitions in commercial and residential spaces.

- Architectural Frames: OHS tubes can be used in creating frame structures for entrance arches, canopies, and signage, combining functional support with visual appeal.

2. Furniture Design and Manufacturing

Oval Hollow Section tubes are commonly used in furniture design because of their combination of strength, light weight, and aesthetic appeal. They are particularly effective in creating modern and stylish furniture pieces.

Key Furniture Uses:

- Furniture Frames: OHS tubes are used in the manufacture of chairs, tables, sofas, and shelves, providing a sleek, modern look while ensuring strength and durability.

- Racks and Stands: They are ideal for creating display racks, TV stands, and storage solutions that require a minimalistic yet strong frame.

- Office Furniture: OHS tubes are commonly used in the construction of office desks, workstations, and conference tables due to their aesthetic and functional properties.

3. Structural Engineering and Construction

While Square Hollow Section (SHS) and Circular Hollow Section (CHS) tubes dominate the structural space, OHS tubes can be employed in specific structural applications where both strength and design flexibility are required.

Key Structural Uses:

- Support Columns: OHS tubes are sometimes used for support columns in high-rise buildings or bridges, offering a balance between strength and aesthetics.

- Bridges: The strength-to-weight ratio of OHS tubes makes them useful in bridge construction, where their shape allows them to withstand bending forces.

- Roof Structures: Due to their unique shape, OHS tubes are used in constructing roof trusses, canopies, and supporting structures for stadiums, airports, and industrial buildings.

- Facades and Cladding: In addition to internal frame applications, OHS tubes are used for exterior cladding systems or facade panels, particularly in modern architecture.

4. Automotive Industry

In the automotive sector, OHS tubes are often used to produce components that require strength, precision, and aesthetic appeal. Their oval shape is particularly useful for specific parts that need to provide efficient energy absorption and high resistance to bending.

Key Automotive Uses:

- Car Frames: OHS tubes are sometimes used in constructing car frames and chassis due to their strength-to-weight ratio and resistance to torsional forces.

- Roll Cages: Oval tubes can be used for roll cages in racing cars, where impact resistance and strength are critical.

- Bumper Systems: The shape of OHS tubes helps to absorb shock energy efficiently, making them suitable for bumper beams or crash absorption systems.

- Automotive Styling: Due to their unique and sleek appearance, they are also used in automotive design elements like grills, side moldings, or roof rails.

5. Renewable Energy Sector

The renewable energy sector, particularly in solar energy and wind energy, benefits from the unique properties of OHS tubes.

Key Renewable Energy Uses:

- Solar Panel Mounting Frames: OHS tubes can be used for the framework of solar panel racks, providing stability and wind resistance, especially for large-scale solar installations.

- Wind Turbine Components: The tubes’ resistance to bending and torsion makes them suitable for support structures of wind turbines, where high strength is needed to support heavy loads.

6. Marine and Offshore Applications

OHS tubes are also utilized in marine and offshore applications, where resistance to harsh environmental conditions and structural integrity are critical.

Key Marine Uses:

- Marine Structures: OHS tubes are used in the construction of marine platforms, offshore drilling rigs, and platform legs that need to resist lateral forces.

- Docking and Boat Frames: The strong, lightweight design of OHS tubes makes them ideal for building boat frames and docking structures.

- Subsea Installations: They are also used for subsea pipelines, support beams, and marine foundations where strength and corrosion resistance are necessary.

7. Sports Equipment

Oval Hollow Section tubes are used in the manufacture of sports equipment because of their ability to withstand high stresses while maintaining an attractive appearance.

Key Sports Uses:

- Goal Posts & Nets: SHS tubes are used in goal posts for sports like football, hockey, and rugby.

- Fitness Equipment: They are used in creating fitness machines, exercise equipment, and gym frames.

- Bicycles: OHS tubes are often employed in the manufacture of bike frames, providing the necessary strength and lightness for better performance.

8. Retail & Display Applications

OHS tubes are commonly used in retail design and display solutions, thanks to their smooth appearance and robustness.

Key Retail Uses:

- Display Fixtures: OHS tubes are used in display racks, showcases, and stands to provide strength and durability while giving an aesthetically pleasing modern design.

- Signage Frames: Their smooth shape and strength make them ideal for signpost frames, billboards, and storefront signage.

- Exhibition Structures: OHS tubes are often used in constructing exhibition stands and booths due to their strength and ease of fabrication.

9. Industrial Applications

OHS tubes are used in a wide range of industrial applications, particularly in frameworks where strength, resistance to torsion, and ability to handle heavy loads are crucial.

Key Industrial Uses:

- Conveyor Systems: OHS tubes are used in the manufacture of support frames and rollers for conveyor belts.

- Piping Systems: Used in high-pressure piping systems, particularly where both strength and aesthetic appeal are required, such as in food processing or pharmaceutical industries.

- Material Handling Equipment: OHS tubes are used in the framework of material handling equipment, such as cranes, lifts, and trolleys.

Advantages of Oval Hollow Section (OHS) Tubes

- Strength and Durability: The oval shape offers excellent structural properties, including high strength, resistance to torsion, and enhanced load-bearing capacity.

- Aesthetic Appeal: The sleek and modern look of OHS tubes is ideal for applications requiring a balance between form and function.

- Efficiency: OHS tubes are more efficient in carrying loads than circular tubes in certain configurations due to their resistance to torsion and bending.

- Lightweight: Despite their strength, OHS tubes are lightweight, which is beneficial for applications where weight reduction is essential.

Conclusion

Oval Hollow Section (OHS) metal tubes are increasingly used in architectural, structural, industrial, automotive, and renewable energy applications due to their unique shape, strength, and aesthetic appeal. Their versatility allows them to meet the demands of a wide range of industries, from modern building designs to sports equipment and automotive manufacturing, making them an ideal choice in both functional and design-driven projects.